AP202 – Plastic Impact Modifier

Fiber Technologies impact modifiers AP101 and AP202 flouroadditives are homogenous blends of Polytetrafluoroethylene (PTFE) and surfactants and/or processing aids. These fluoroadditives are different from well-known Teflon® molding and extrusion powders. Fiber Technologies fluoroadditives are used for solid elastomer modification.

Solid elastomers modified with Fiber Technologies are then used as impact modifiers (Fiberprene) for plastics.

Fiber Technologies AP 101 modifies physical performance characteristics of Elastomers:

- Tear strength

- Tensile strength

- Modulus

- Abrasion resistance

- Coefficient of friction

- Elastic recovery

- Stiffness

- Durability

Fiber Technologies AP 101, a plastic impact modifier, impart unique features into Elastomers and Plastics:

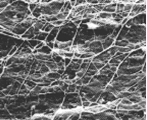

- Fiber matrix (fig 1,2)

- Internal lubricity

- Improved mold release

- Improved green strength

- Chemical resistance

- Resistance to part deformation

- Improved physical performance (Hot & Cold)

AP101 Use in Asphalt

Fiber Technologies AP 101 is a composition of Polytetrafluoroethylene (PTFE) and select minerals. AP 101 mixed under the correct mixing guidelines creates a unique three dimensional intermeshing matrix of PTFE  fibers coated with select surfactants and processing aids. Structural reinforcement is created by the addition of AP 101 fibers into the asphalt mix. In order to create the fiber network, AP 101 needs a “carrier” into the liquid asphalt. The “carriers” of choice are called ThermoPlastic Elastomers or TPE’s for short. The AP 101 fiber network increases the physical properties performance of the TPE, thereby increasing the performance grade of the asphalt. Additionally, the fiber network in AP 101 helps to evenly coat the liquid asphalt over the aggregate. Fewer air voids lead to increased durability of the road pavement. Asphalt flow is the root cause of most asphalt failures. AP 101 modified asphalt can make a dramatic difference in the performance due to its ability to create “memory” within the asphalt. This memory is imparted into the asphalt by the fiber formation created by the AP 101 and TPE described above

fibers coated with select surfactants and processing aids. Structural reinforcement is created by the addition of AP 101 fibers into the asphalt mix. In order to create the fiber network, AP 101 needs a “carrier” into the liquid asphalt. The “carriers” of choice are called ThermoPlastic Elastomers or TPE’s for short. The AP 101 fiber network increases the physical properties performance of the TPE, thereby increasing the performance grade of the asphalt. Additionally, the fiber network in AP 101 helps to evenly coat the liquid asphalt over the aggregate. Fewer air voids lead to increased durability of the road pavement. Asphalt flow is the root cause of most asphalt failures. AP 101 modified asphalt can make a dramatic difference in the performance due to its ability to create “memory” within the asphalt. This memory is imparted into the asphalt by the fiber formation created by the AP 101 and TPE described above

![]() Comparison of Fiber Technologies Modified TPE’s and Neat Asphalt

Comparison of Fiber Technologies Modified TPE’s and Neat Asphalt

Fiber Technologies Fiber Product benefits

- The base polymer in AP 101 is PTFE. Polytetrafluoroethylene has unique properties. PTFE is virtually inert to chemicals and solvents.

- PTFE resists flame ignition and itself does not promote flame spread or significant smoke.

- Dielectric properties of PTFE are excellent and stable over wide ranges of temperature and frequency.

- Fiber Technologies PTFE forms a three-dimensional intermeshing network of fibers (fig 1,2 ).

- Fiber Technologies PTFE imparts a mechanical enhancement into Elastomers and Plastics.

- PTFE can affect the behavior of materials without reacting with them or contaminating mix design or work environments.

- PTFE is non-hazardous

- PTFE has a low Coefficient of Friction

- PTFE is insoluble in water

- PTFE does not discolor or degrade in sunlight or high temperatures.

- Fiber Technologies PTFE is compatible with all Elastomers and Plastics

- Fiber Technologies PTFE can help increase production and reduce scrap rates

- Facilitates the use of recycled products

- Helps to impart fire resistant properties

**The PTFE network is formed and completed during compounding. It requires high shear to fracture and disperse the fiber network into usable form. Banbury mixing equipment is preferred for compounding and dispersion.